Pegasus Manufacturing Inc. uses advanced CNC machines to deliver high-precision parts for industries like defense, aerospace, and medical. Our multi-axis turning centers, milling systems, and machining centers ensure every part meets strict quality and performance standards — from prototype to production.

| Make | Qty. | Type | Travel – (in.) | Spindle Power & Speed | CNC System |

|---|---|---|---|---|---|

| Jupiter Machine Tool VMX650FX WLMD | 2 | Traveling Column | X: 27.56″ Y: 22.05″ Z: 18.7″ B: Swiveling Range -90°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc 31i-B5 w/ 21.5″ Color Touch Screen |

| Jupiter Machine Tool VMC4024 WLMD | 1 | 3+2 | X: 40″ Y: 24″ Z: 24″ B: Swiveling Range -90°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc Oi-TF+ 15″ Touchpanel Color Touch Screen |

| Make | Qty. | Type | Travel – (in.) | Spindle Power & Speed | CNC System |

|---|---|---|---|---|---|

| Jupiter Machine Tool VMX650FX | 2 | Traveling Column | X: 27.56″ Y: 22.05″ Z: 18.7″ B: Swiveling Range -90°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc 31i-B5 w/ 21.5″ Color Touch Screen |

| Jupiter Machine Tool VMG650FX | 1 | Gantry | X: 25.59″ Y: 32.28″ Z: 21.65″ B: Swiveling Range -100°~+120° C: Rotary Axis 360° | 35hp 20,000rpm | Fanuc 31i-B5 / PLUS w/ 15″ Touchpanel |

| Jupiter Machine Tool VMX320FX | 1 | C-Frame | X: 16.1″ Y: 24″ Z: 20″ B: Swiveling Range -100°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc 31i-B5 / PLUS |

| Make | Qty. | Axis | Travel – (in.) | Spindle Power & Speed | CNC System |

|---|---|---|---|---|---|

| Jupiter Machine Tool VMC4024 | 1 | 3+2 | X: 40″ Y: 24″ Z: 24″ B: Swiveling Range -90°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc Oi-TF+ 15″ Touchpanel Color Touch Screen |

| Jupiter Machine Tool VMC4328b | 1 | 3 | X: 25.59″ Y: 32.28″ Z: 21.65″ B: Swiveling Range -100°~+120° C: Rotary Axis 360° | 35hp 20,000rpm | Fanuc Oi-TF+ 15″ Touchpanel Color Touch Screen |

| Jupiter Machine Tool VMC5020 | 2 | 3+1 | X: 16.1″ Y: 24″ Z: 20″ B: Swiveling Range -100°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc Oi-TF+ 15″ Touchpanel Color Touch Screen |

| Jupiter Machine Tool VMC622 | 1 | 3 | X: 16.1″ Y: 24″ Z: 20″ B: Swiveling Range -100°~+120° C: Rotary Axis 360° | 44hp 15,000rpm | Fanuc Oi-TF+ 15″ Touchpanel Color Touch Screen |

| Jupiter Machine Tool VMT430 | 1 | 3 | X: 16.1″ Y: 24″ Z: 20″ B: Swiveling Range -100°~+120° C: Rotary Axis 360° | 44hp 20,000rpm | Fanuc Oi-TF+ 15″ Touchpanel Color Touch Screen |

| Make | Qty. | Type | Travel – (in.) | Table Size | Spindle Power & Speed | CNC System |

|---|---|---|---|---|---|---|

| Jupiter Machine Tool HMC400 | 4 | Traveling Column | X: 24″ Y: 20″ Z: 20″ Dual Pallet | 400 mm | 44 hp 12,000 rpm | Fanuc Oi-TF+ 15″ Touchpanel |

| Jupiter Machine Tool HMC500 | 1 | Gantry | X: 32″ Y: 30″ Z: 30″ Dual Pallet | 500 mm | 44 hp 20,000 rpm | Fanuc Oi-TF+ 15″ Touchpanel |

| Make | Qty. | Axis | Spindle Speed | Chuck Size | Max Turning Diameter | Max Working Length | CNC System |

|---|---|---|---|---|---|---|---|

| Jupiter Machine Tool JHL3020MYS | 2 | 5 | 3,500 rpm | A-8 Primary Chuck | 18.11″ In. | 30″ In. | Fanuc Oi-TF+ 15″ Touchpanel |

| Jupiter Machine Tool JHL3020MY | 2 | 5 | 3,500 rpm | A-8 Primary Chuck w/ Tail Stock w/Bar Feed | 18.11″ In. | 30″ In. | Fanuc Oi-TF+ 15″ Touchpanel |

| Jupiter Machine Tool JHL2016 Lathe | 1 | 2 | 3,500 rpm | A-6 Primary Chuck | 11.81″ In. | 17.44″ In. | Fanuc Oi-TF+ 15″ Touchpanel |

| Okuma Geno L370 Captain | 1 | 2 | 5,000 rpm | A-8 Primary Big Bore Chuck | 14.57″ In. | 19.68″ In. | Okuma OSP-P500 |

| Okuma LB3000MYS | 1 | 5 | 4,500 rpm | A-8 Primary Big Bore Chuck | 16.14″ In. | 19.69″ In. | Okuma OSP-P500 |

| Okuma LB3000MY | 1 | 5 | 4,500 rpm | A-10 Primary Big Bore Chuck | 22.8″ In. | 51.18″ In. | Okuma OSP-P500 |

| Vivia Turn MY A-10 | 1 | 4 | 4,000 rpm | A-8 Primary Big Bore Chuck | 21.88″ In. | 39.4″ In. | Fanuc Oi-Mate CNC |

| Make | Qty. | Type | Travel – (in.) | Probing System | CNC System |

|---|---|---|---|---|---|

| Zeiss Eclipse | 1 | Bridge w/ 5-Axis | X: 40″ Y: 40″ Z: 20″ A: 360° B: 260° | RDS TP 20 | Calypso |

| Zeiss Spectrum | 1 | Bridge w/ 5-Axis | X: 27.5″ Y: 27.5″ Z: 21.5″ A: 360° B: 260° | RDS TP 20 | Calypso |

| Zeiss Duramax | 1 | Cantilever | X: 19.5″ Y: 19.5″ Z: 19.5″ A: 360° B: 260° | VAST XXT | Calypso |

For over 20 Years, Pegasus Mfg. Inc. has been providing precision machining services & custom tooling solutions from our state-of-the-art facility. Our wide range of machining capabilities and value-added services allow us to deliver various complex custom–machined components and assemblies to various industries worldwide. As part of our capabilities, we offer multi-axis CNC milling services. Our 3-, 4-, and 5-axis milling machines enable us to create ultraprecise and complex machined results to meet the specific needs of our customers.

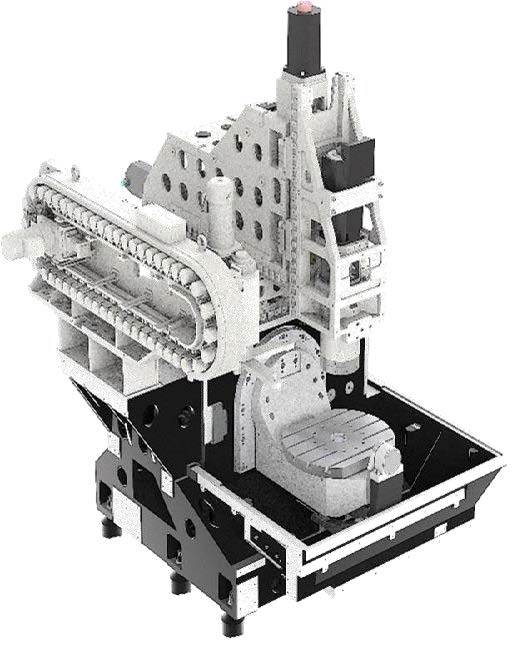

The VMX650 WLMD is built on a Traveling Column design, delivering rigidity, power, and precision for advanced 5-axis hybrid machining. Integrated with Wire-Laser Metal Deposition (WLMD) technology, it enables both additive and subtractive manufacturing in a single setup.

The machine supports options like pallet pools, programmable pneumatic or hydraulic doors, and through-table clamping. All automation features are M-code programmable for efficient lights-out operation. Powered by the FANUC 31i-B5 control, it offers simultaneous X, Y, Z, A, and C axis motion for highly complex parts.

Equipped with 35/45/45mm roller linear guides and Ø45mm pre-tensioned C2 ball screws, it ensures high repeatability and accuracy. The A-axis features a Heidenhain rotary encoder, and the Dual Contact CAT.40 spindle provides rigid machining with reduced tool wear. An HSK A63 spindle is also available.

• Rotary Table Diameter: Ø25.59” x 20.47” (Ø650×520 mm)

• Max Work Envelop Size: 21.17” (Ø650 mm) Height: 18.11″ (460 mm)

• Max Table Load: 661.39 lbs./ 661.39 lbs (300kg/ 300kg)

• X/ Y/ Z Axis Travel: 27.56”/ 22.05”/ 18.70” (700/ 560/ 475mm)

• Tilt Axis (B Axis), Swiveling Range -90~ +120°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis) 360°; with Heidenhain ECN Rotary Encoder

The VMX650FX-WLMD 5 axis traveling bridge machine center features a table size of Ø650 mm, and a work envelope size applicable for complicated simultaneous contouring required for high accuracy machining applications. Superior +/- 3 microns machine accuracy increases profits and reduces scrap. This machine is designed to support the aerospace, medical, molding, automotive and other advanced industries.

The NEW JUPITER VMC4024-WLMD is a Premium Hybrid Additive-Subtractive CNC machine center which combines high performance speed and accuracy with an integrated Wire Laser Metal Deposition (WLMD) patented system by MELTIO. The new Jupiter CNC Machine Additive System is “Power by Meltio” and prints 3D metal parts using wire not powder. The WLMD system offers a selection of 14 different metal types such as Mild steel, Stainless Steel, Alloy Steels, Titanium, and others. The 3D part is printed to a “Near Net Finish” (within .040”) shape which dramatically reduces machine cycle time, fixtures, design and machined work holding, tooling, and setup time.

• Max Work Envelop Size: Ø450 x 460mm

• Max Work Envelop Size: Ø450 x 460mm

• Machine Type: 3 & 5 Axis Hybrid

• Machine Type: 5 Axis Hybrid Bridge

• Rotary Table Diameter: Ø25.59” x 20.47” (Ø650×520 mm)

• Rotary Table Diameter: (Ø650 mm)

• X/ Y/ Z Axis Travel: 27.56”/ 22.05”/ 18.70” (700/ 560/ 475mm)

• X/ Y/ Z Axis Travel: 18.1″ / 24.0″ / 20.0″ / 20.0″ (700/ 560/ 475mm)

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis): 360°

• Max Table Load: 661.39 lbs./ 661.39 lbs (300kg/ 300kg)

• Max Table Load: 220 lbs. ( 300kg)

The JUPITER HMC-800P Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Automotive, Mold & Die, Heavy Equipment, and many other critical applications.

The HMC series is engineered in a symmetrical T-base design for improved stiffness thermal control. High Precision 45/45/45mm roller linear guides are used with robust Ø50mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 60 tool ATC with 120 tools available. High precision Big Plus #50 with two face clamping for rigid machining and reduced tool wear.

The JUPITER HMC-500 Horizontal Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Automotive, Mold & Die, Heavy Equipment, and many other critical applications.

The HMC series is engineered in a symmetrical T-base design for improved stiffness thermal control. High Precision 45/45/45mm roller linear guides are used with robust Ø45mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 40 tool ATC, optional 60 Tool ATC available. High precision dual contact CAT 40 spindle with two face clamping for rigid machining and reduced tool wear.

• X / Y / Z Axis Travel: 50.0″ / 41.3” / 41.35” (1270 / 1050 / 1050mm)

• X / Y / Z Axis Travel: 31.5″ / 31.5” / 31.5” (800 / 800 / 800mm)

• Work Table Size: 31.5” x 31.5” (800mm x 800mm)

• Work Table Size: 19.69” x 19.69” (500mm x 500mm)

• Full Contouring B axis: +/- 360° (0.001°)

• Full Contouring B axis: +/- 360° (0.001°)

• Machine Weight: 72,600 lbs / ( 33,000 kg )

• Machine Weight: 29,760 lbs / ( 13,500 kg )

• Max Table Load: 5,500 lbs ( 2,500 kg )

• Max Table Load: 1,323 lbs ( 600 kg )

• Repeatability Accuracy: 0.00015” In ( 0.004 mm)

• Repeatability Accuracy: 0.00015” In ( 0.004 mm)

• Positioning Accuracy: 0.00019” in ( 0.005 mm )

• Positioning Accuracy: 0.00019” in ( 0.005 mm )

• Spindle Nost to Table: 1.97” – 43.3” in (50 – 1100 mm )

• Spindle Nost to Table: 5.91″ 37.4″ ( 150 – 950 mm )

The JUPITER HMC-400 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Automotive, Mold & Die, Heavy Equipment, and many other critical applications.

The HMC series is engineered in a symmetrical T-base design for improved stiffness thermal control. High Precision 45/45/45mm roller linear guides are used with robust Ø50mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 60 tool ATC with 120 tools available. High precision Big Plus #50 with two face clamping for rigid machining and reduced tool wear.

The JUPITER HMC-380 Horizontal Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Automotive, Mold & Die, Heavy Equipment, and many other critical applications.

The HMC series is engineered in a symmetrical T-base design for improved stiffness thermal control. High Precision 45/45/45mm roller linear guides are used with robust Ø45mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 40 tool ATC, optional 60 Tool ATC available. High precision dual contact CAT 40 spindle with two face clamping for rigid machining and reduced tool wear.

X / Y / Z Axis Travel: 23.62″ / 19.69 ” / 19.69″ (600 / 500 / 500 mm)

X / Y / Z Axis Travel: 31.5″ / 31.5” / 31.5” (800 / 800 / 800mm)

Full Contouring B axis: +/- 360° (0.001°)

Full Contouring B axis: +/- 360° (0.001°)

Work Table Size: 31.5” x 31.5” (800mm x 800mm)

Work Table Size: 19.69” x 19.69” (500mm x 500mm)

Pallet Max Load: 880 lbs ( 400 kg )

Max Table Load: 1,323 lbs ( 600 kg )

Repeatability Accuracy: 0.000118” In ( 0.000118 mm)

Repeatability Accuracy: 0.00015” In ( 0.004 mm)

Positioning Accuracy: 0.000157” in ( ±0.0039878 mm )

Positioning Accuracy: 0.00019” in ( 0.005 mm )

Spindle Nost to Table: 3.94″ in (100 mm)

Spindle Nost to Table: 5.91″ 37.4″ ( 150 – 950 mm )

Machine Weight: 12,100 lbs / ( 5,489 kg )

Machine Weight: 29,760 lbs / ( 13,500 kg )

The JUPITER VMC-4024 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

This machining center is engineered in a unique wide column design for an excellent foundation. High Precision 35/45/45mm roller linear guides are used with robust Ø45mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard side mount 30 tool ATC with max tool diameters of 75mm/150mm, with/without adjacent tools. High precision Big Plus #40 with two face clamping for rigid machining and reduced tool wear.

The Jupiter VMC-3016 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.Vertical Machining Center Heavily Ribbed Casting.

The frame is built from high quality, high tensile MEEHANITE FC30 naturally aged cast iron provides outstanding wear resistance and rigidity.

• X / Y / Z Axis Travel: 40.2″ / 24″ / 24″ 1020 / 610 610 mm)

• X / Y / Z Axis Travel: 29.52 / 15.75″ / 17.722″ 750 / 400 / 450 mm)

• Max Work Envelop Size: 47.25″ x 23.6″ (1200 mm x 600 mm)

• Max Work Envelop Size: 47.25″ x 23.6″ (1200 mm x 600 mm)

• Max Table Load: 1,980 lbs. / 1,980 lbs. (750 kg / 750 kg.)

• Max Table Load: 1,100 lbs. / 1,100 lbs (499 kg / 499 kg)

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Spindle Nost to Table: 3.9” – 27.9” in (100 – 710 mm)

• Spindle Nost to Table: 5.91” – 23.62” in (150– 600 mm)

• Machine Weight 16,060 lbs. / (7,300 kg.)

• Machine Weight 14,300 lbs. / ( 6486 kg )

• Positioning Accuracy: 0.00019” in ( 0.005 mm )

• Positioning Accuracy: 0.000157″ in ( 0.005 mm )

• Repeatability Accuracy: 0.00015” In ( 0.004 mm)

• Repeatability Accuracy: 0.000118” In ( 0.0029 mm)

The JUPITER VMC-6330 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

The VMC series is engineered in a unique wide column design for an excellent foundation. High Precision 45/55/45mm roller linear guides are used with robust Ø50mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 48 tool ATC with max tool diameters of 75mm/150mm, with/without adjacent tools. Features a high precision BBT40 spindle with two face clamping for rigid machining and reduced tool wear

The JUPITER VMC-8030 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

The VMC series is engineered in a unique wide column design for an excellent foundation. High Precision 45/55/45mm roller linear guides are used with robust Ø50mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 48 tool ATC with max tool diameters of 75mm/150mm, with/without adjacent tools. Features a high precision BBT40 spindle with two face clamping for rigid machining and reduced tool wear

• X / Y / Z Axis Travel: 62.3″ / 29.5″ / 29.5″ ( 1600 / 750 / 750 mm )

• X / Y / Z Axis Travel: 79.9 / 29.75″ / 38.722″ ( 2029 / 755 / 984mm )

• Max Work Envelop Size: 68.9” x 27.6″ ( 1750 mm x 700 mm )

• Max Work Envelop Size: 84.25″ x 29.6″ (1200 mm x 600 mm )

• Max Table Load: 3,968 lbs / 13,968 lbs (1,800 kg / 1,800 kg )

• Max Table Load: 1,100 lbs. / 1,100 lbs (499 kg / 499 kg )

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Spindle Nose to Table: 3.9” – 33.46” in ( 100 – 850 mm )

• Spindle Nose to Table: 5.91” – 23.62” in (150– 600 mm )

• Machine Weight 26,000 lbs. / ( 12,000 kg )

• Machine Weight 32,000 lbs / ( 14,515 kg )

• Positioning Accuracy: 0.00019” in ( 0.005 mm )

• Positioning Accuracy: 0.000157″ in ( 0.005 mm )

• Repeatability Accuracy: 0.00015” In ( 0.004 mm)

• Repeatability Accuracy: 0.000118” In ( 0.0029 mm )

The JUPITER VMC-4022 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

The VMC series is engineered in a unique wide column design for an excellent foundation. High Precision 45/55/45mm roller linear guides are used with robust Ø50mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 48 tool ATC with max tool diameters of 75mm/150mm, with/without adjacent tools. Features a high precision BBT40 spindle with two face clamping for rigid machining and reduced tool wear

The JUPITER VMC-7036 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

The VMC series is engineered in a unique wide column design for an excellent foundation. High Precision 45mm roller linear guides are used with robust Ø45mm pre-tensioned C3 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 24 tool ATC with max tool diameters of 75mm/150mm, with/without adjacent tools. Features a High precision CATT40 Spindle with two face clamping for rigid machining and reduced tool wear.

• X / Y / Z Axis Travel: 40.16″ / 21.65″ / 20.08″ In ( 1020 / 550/ 510 mm )

• X / Y / Z Axis Travel: 70.9″ / 35.4” / 29.5” (1600 / 750 / 750mm)

• Max Work Envelop Size: 47.27” x 20.87″ In ( 1200 mm x 530 mm )

• Max Work Envelop Size: 84.25″ x 29.6″ (1200 mm x 600 mm )

• Max Table Load: 1,320 lbs / 1,320 lbs (599 kg / 599 kg )

• Max Table Load: 68.9” x 27.6” (1750mm x 700mm)

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis):

• Machine Weight 14,300 lbs. / ( 6486kg )

• Machine Weight 12,000 lbs (26,400 kg)

• Spindle Nose to Table: 5.91” – 26.00” in ( 150 – 660 mm )

• Spindle Nose to Table: 3.94” – 33.46” (100 – 850 mm)

• Positioning Accuracy: 0.000157” in ( 0.003978 mm )

• Positioning Accuracy: .0002” (.006mm)

• Repeatability Accuracy: 0.000118” In ( 0.0029972 mm)

• Repeatability Accuracy: 0.00015”(.004mm)

The JUPITER VMT-430 is a high-performance vertical machining twin designed to deliver unmatched volumetric accuracy and exceptional value across precision-critical industries including aerospace, medical, and mold & die applications.

Engineered with best-in-class build quality, the VMT-430 features dual Big Plus #40 taper spindles running at 12,000 RPM and delivering 17.4 HP of cutting power. Jupiter guarantees circularity within 0.008mm (.0003″) or less in all three planes—thanks to high-grade components, fine-tuned assembly, and precision ballbar testing on every machine.

With rapid traverse rates of 1,417 IPM on all axes and a robust 24×2 side-mount automatic tool changer, the VMT-430 is built for speed, accuracy, and flexibility. Its compact footprint (75.6” x 122” x 108”) and large working envelope (X/Y/Z: 18.9” / 17.1” / 17.7”) make it ideal for high-output environments where precision cannot be compromised.

• Travel of X /Y / Z :18.9” / 17.1” / 17.7”

• Rapid Rate X / Y / Z : 1,417 ipm / 1,417 ipm / 1,417 ipm

• Max Turning Diameter: : Ø2.95”

• Max Turning Length: 7″

• Machine Weight: 11,000 lbs

• Turning Spindle Main: 12,000 rpm max

The JUPITER CM-2016 Compact High Speed Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

The CM series is engineered in a unique “C” frame design for an excellent foundation. High Precision 30mm roller linear guides are used with robust Ø32mm pre-tensioned C1 class ball screw for reliable accuracy on X/Y/Z Axes.

High precision Big Plus #40 or BBT30 with two face clamping for rigid machining and reduced tool wear.

The JUPITER CM-2816 Compact Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

The CM series is engineered in a unique “C” frame design for an excellent foundation. High Precision 30mm roller linear guides are used with robust Ø32mm pre-tensioned C1 class ball screw for reliable accuracy on X/Y/Z Axes.

High precision Dual Contact CAT40 or Dual Contact CAT30 with two face clamping for rigid machining and reduced tool wear.

• Max Work Envelop Size: 25.6” x 16.14″ in (650 x 410 mm)

• Max Table Load: 300 lbs. / 300 lbs ( 136 kg / 136 kg)

• X/ Y/ Z Axis Travel: 19.7” / 15.75” / 17.7” (500 / 400 / 450 mm)

• Spindle Nose to Table: 5.12″ – 22.83″ in ( 130 – 580 mm)

• Max Work Envelop Size: 33.46” x 16.14″ in (850 x 410 mm)

• Max Table Load: 300 lbs. / 300 lbs ( 136 kg / 136 kg)

• X/ Y/ Z Axis Travel: 27.5” / 15.75” / 17.7” (700 / 400 / 450 mm)

• Spindle Nose to Table: 5.12″ – 22.83″ in ( 130 – 580 mm)

The JUPITER JHL-MY series of turning centers is a heavy duty, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. With bar capacity up to Ø 3.0”, subspindle or tailstock options this series offers great flexibility. The high performance, no-compromise platform satisfies Medical, Aerospace, Energy, and job shops requiring high productivity and robust applications.

The JHL-MY series is engineered in a 30 Degree Slant Bed for an excellent foundation. The Y axis rides on a 15-degree slant for maximum power and space savings. FEA designed Meehanite casting structure can withstand greater stress without deforming and provides ultimate vibration damping. High Precision integral box ways for maximum rigidity and accuracy.

Ground pre-tensioned ball screws for reliable precision on all linear axes. The available subspindle and parts catcher bring quick automation to your next job. All MY series machines include a BMT60 live tool servo turret to increase your production flexibility with 6hp and 6,000 rpm.

The Jupiter JHL series of turning centers is a compact, premium machine tool, designed to feature maximum capacity and performance in many demanding industries.

The high performance, no-compromise platform satisfies automotive, medical, defense and many other critical applications.

The JHL series is engineered with a 45 Degree Slant Bed for an excellent foundation. Torque tube Meehanite casting structure can withstand greater stress without deforming and provides maximum vibration damping. High Precision box ways are integral of the casting for maximum rigidity and accuracy.

Robust pre-tensioned ball screws for reliable precision on X/Z axes. Powerful Fanuc motor provides 20 HP on the turning spindle with 2” bar capacity standard. The optional BMT55 live tool servo turret increases your production flexibility with 7.5hp and 6,000 available rpm.

Direct feedback glass scales are available as options for the highest consistency and accuracy with maximum reliability.

• Travel of X / Y / Z / ZB / C1 / C2: (310 / 110 / 620 / 650mm / 360° / 360°)

• Travel X / Z: 11.42” / 25.20” (290mm / 640mm)

• Rapid Rate X / Y / Z / ZB: 787ipm (20m/min)

• Rapid Rate X / Z: 787ipm (20m/min)

• Max Turning Diameter: Ø18.11” (460mm)

Max Turning Diameter: Ø20.08” (510mm)

• Max Turning Length: 21.6” (548mm)

• Max Turning Length: 23.39” (594mm)

• Turning Spindle Bar Capacity (Main): Ø3.0” (77mm)

• Machine Weight: 14,300 lbs

• Turning Spindle Nose (Main): A2-8, 3,500rpm max

• Turning Spindle Nose (Sub): A2-5, 6,000rpm max

• Turning Spindle Nose: A2-8, 2,500rpm max

• Turning Spindle Bar Capacity (Sub): Ø2.0” (52mm)

• Spindle Motor Power: 20 / 25 hp (continuous / 30 min)

• Machine Dimensions (W x D x H): 153″ x 79″ x 84″

The VMX650FX-WLMD 5 axis traveling bridge machine center features a table size of Ø650 mm, and a work envelope size applicable for complicated simultaneous contouring required for high accuracy machining applications. Superior +/- 3 microns machine accuracy increases profits and reduces scrap. This machine is designed to support the aerospace, medical, molding, automotive and other advanced industries.

The JupiterVMX320 FX Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance. The compact footprint, yet powerful platform satisfy Mold & Die, Medical, Automotive and many other critical applications.

• Max Work Envelop Size: 21.17” (Ø650 mm) Height: 18.11″ (460 mm)

• Max Work Envelop Size: Ø12.6″ (Ø320 mm) Height: 21.2″ (460 mm)

• Tilt Axis (B Axis), Swiveling Range: -90 ~ +120°; with Heidenhain ECN Rotary Encoder

• Tilt Axis (B Axis), Swiveling Range: +30 ~ +120°; with Heidenhain ECN Rotary Encoder

• Rotary Table Diameter: Ø25.59” x 20.47” (Ø650×520 mm)

• Rotary Table Diameter: Ø12.6″ x 20.47” (Ø320 mm)

• X/ Y/ Z Axis Travel: 27.56”/ 22.05”/ 18.70” (700/ 560/ 475mm)

• X/ Y/ Z Axis Travel: 18.1″ / 24.0″ / 20.0″ / 20.0″ (700/ 560/ 475mm)

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Max Table Load: 661.39 lbs./ 661.39 lbs (300kg/ 300kg)

• Max Table Load: 220 lbs. / 220 lbs. (100kg / 300kg)

The Jupiter Hurricane 650 5-Axis Gantry machine center features a table size of Ø650 mm, and a work envelope size applicable for complicated simultaneous contouring required for high accuracy machining applications. Superior +/- 3 microns machine accuracy increases profits and reduces scrap. This machine is designed to support the aerospace, medical, molding, automotive and other advanced industries.

The JUPITER VMX650 FX Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Automotive and many other critical applications.

• Rotary Table Diameter: Ø25.59” x 20.47” (Ø650 × 520 mm)

• Rotary Table Diameter: Ø25.5″ (Ø650 mm)

• Max Work Envelop Size: 21.17” (Ø650 mm) Height: 18.11″ (460 mm)

• Max Work Envelop Size: Ø12.6″ (Ø320 mm) Height: 21.2″ (460 mm)

• Max Table Load: 1,650 lbs./ 661.39 lbs (750kg / 750kg)

• Max Table Load: 220 lbs. / 220 lbs. (100kg / 300kg)

• X/ Y/ Z Axis Travel: 25.59″ / 32.28″ / 21.65″ (650 / 820 / 550 mm)

• X/ Y/ Z Axis Travel: 24.4″ / 20.4″ / 18.1″ (620 / 520 / 460 mm)

• Tilt Axis (A Axis), Swiveling Range: +100° ~ -120°; with Heidenhain ECN Rotary Encoder

• Tilt Axis (B Axis), Swiveling Range: +30 ~ +120°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Rotary Axis (C Axis): 360°; with Heidenhain ECN Rotary Encoder

• Machine Weight 22,000 lbs. / (9,980 kg.)

• Machine Weight 16,280 lbs. / (7,400 kg.)