Fast. Accurate. Adaptable.

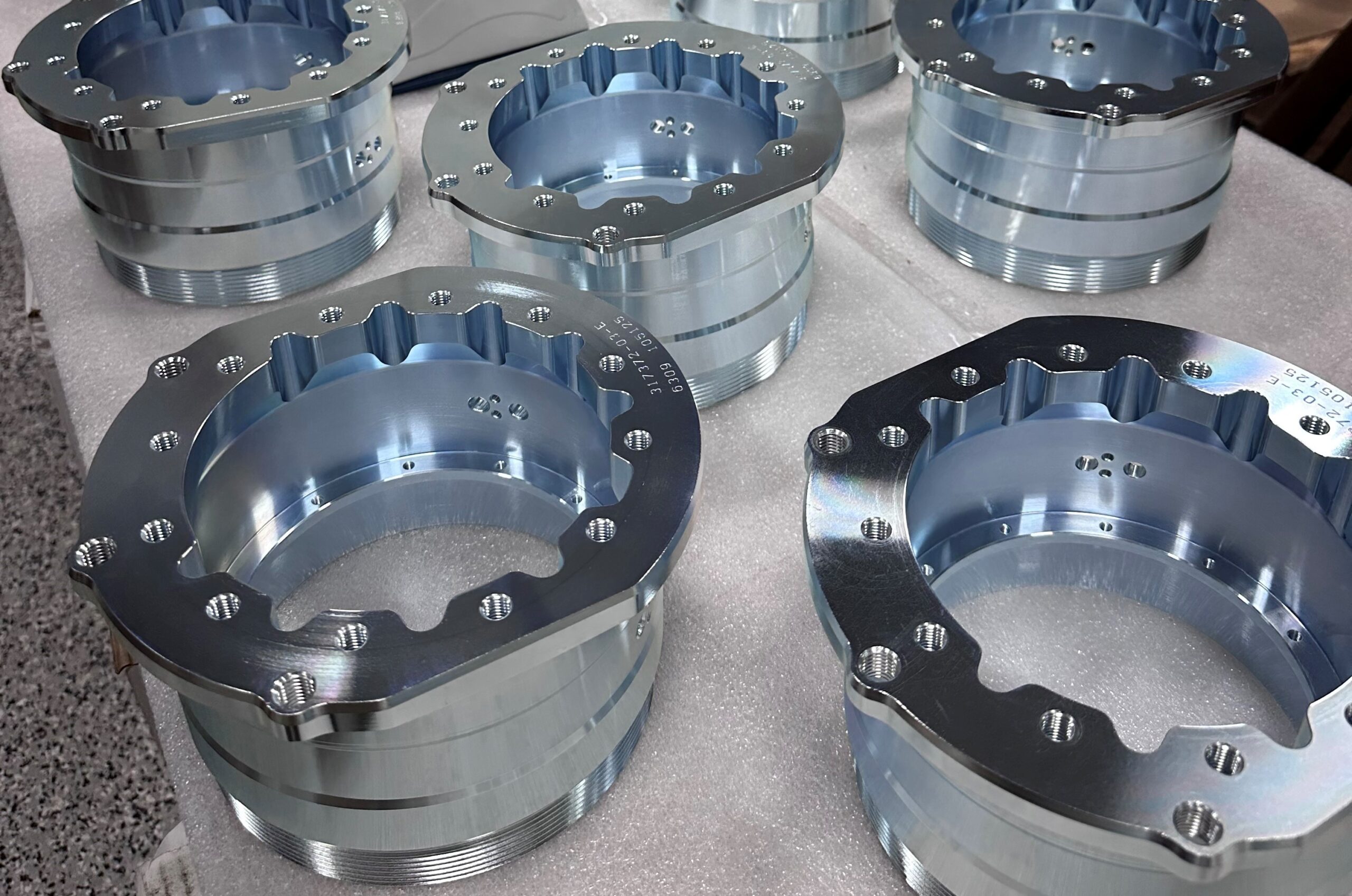

At Pegasus Manufacturing, we deliver high-performance CNC milling solutions that power industries ranging from aerospace and medical to energy and automation. Whether it's a high-spec component or a large structural element, our advanced 3-axis and 5-axis machining centers offer unmatched precision and versatility.

CNC (Computer Numerical Control) milling is a modern subtractive manufacturing process where computer-guided rotating tools shape raw materials into finished parts. It transforms a digital model into a physical product by removing material with multi-axis control, enabling the creation of highly complex and accurate components.<br>

Using advanced software and automation, Pegasus ensures cost-efficient manufacturing without compromising quality or customization.

At Pegasus Manufacturing, our ISO-certified shop is home to some of the most advanced CNC equipment in the country. Our facility supports large-part CNC milling, simultaneous 5-axis contouring, and hybrid additive-subtractive operations.

VMX650FX-WLMD 5-Axis Hybrid – Additive-subtractive milling with Meltio wire-laser technology.

4-Axis and 5-Axis VMCs – High-speed machining for complex contours.

Traveling Bridge Machine Centers – Rigid, thermally stable machining for large parts.

With Fanuc 31i-B5 controllers, rotary encoders, dual-contact spindles, and 48+ tool ATCs, we achieve micron-level precision and minimize cycle times.